Testing, testing, 1,2,3… How we solve problems when prototyping

At PDR, we use a wide range of tools to turn ideas into reality - but innovation isn't always smooth sailing. Product Designer, David Balaam, talks about navigating the world of prototyping and tackling issues head-on - and shares how we handle the crucial testing stage when developing new products or services.

"We can prototype in several different ways. Digital prototypes like 3D models can give us a real feel of the shape and scale of what we're working on," says David. "It can be a game-changer when we model large projects like buildings and spaces or small quick concepts to give our ideas some tangibility for clients to have a first look at."

Rapid prototyping is very useful, this can mean quick 3D prints or models from paper or card. We use materials that are easy to find, or even getting items from the local hardware shop to repurpose. "Getting an idea out of your head and in front of others is vital, the quicker the better. Find the pros, cons and potential of an idea and then do it again, test and refine.”

Prototyping at PDR serves multiple purposes; from initial idea exploration to the verification of concepts. But the final phase of prototyping is pre-production testing, where all elements, including scales, sizes, components and materials, are put through a rigorous assessment to make sure the final product will ‘work’ how we need it to.

But these prototyping processes need robust capabilities and facilities.

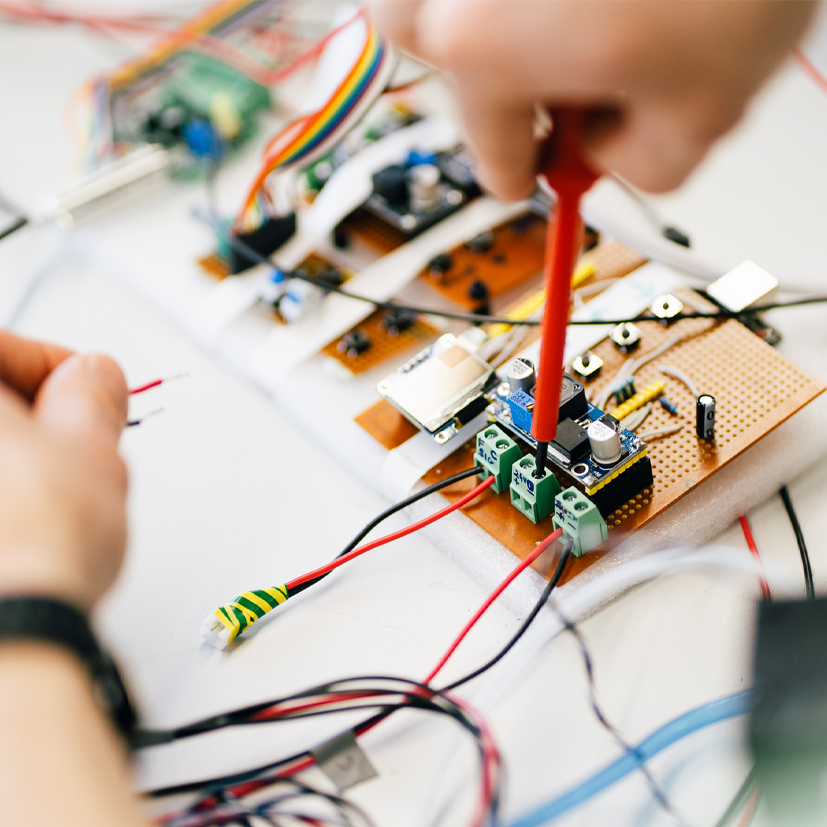

At PDR we have a team of 15 designers and a dedicated prototyping technician, all with a well-rounded skill-set. Their physical resources include a workshop, a print room, and a specialised MVP (Minimum Viable Product) room, focused on electrical work.

“When I first joined PDR, these facilities stood out to me personally because of my hands-on background as a boat builder and carpenter. It's refreshing to have the ability to turn ideas into physical creations, sharing and refining them with other designers and management,” David says. “I think most importantly, being able to physically put them into the hands of clients - it’s been so valuable when designing.” Our commitment to practical, real-world design and prototyping is how we make ideas become reality.

Of course, producing working prototypes and rigs comes with its challenges. “Imaginations are powerful tools, it can be a real challenge to create a product that lives up to someone’s imagination, we don’t have all the technology yet so we have to come up with some interesting work arounds”.

“Another challenge lies in recognising that different people have different ways of using a product. What a designer imagines might not be how users will actually use it. That’s why testing and understanding a range of users perspectives is essential.”

This process of assessing and testing means we’ll discover new things to consider, giving us the opportunity to adjust the design as we go.

David continues, “To give you an example of this, in one of my initial projects, we were asked to redesign a product. To begin, we needed a deeper understanding of its functionality. As we tested the item, we began to notice inconsistencies, but we didn’t understand why.”

“We quickly had to become ‘mini-experts’ in pumps and fluids mechanics. We researched everything we could find on it - from online literature to YouTube videos – learning the technical detail, so we could accurately communicate with manufacturers and specialists to troubleshoot problems and start improving and redesigning.”

“We also called on some of our sub-contractors and contacts in manufacturing to help us bridge the knowledge gap. This process of learning, experimenting, and collaborating was so important when developing the working prototype.”

It’s this diligent approach to prototyping models and using deeper research methods in the testing phase that leads to successful end products and designs, be it a physical item or a digital service. We’re passionate about helping clients turn their ideas into reality - on screen or in their hands - and helping to solve problems in the design process. Explore more about our expertise and how we work.

Next steps

Discover more about PDR or contact us to discuss a product idea.