Designing with the planet in mind: How working on concepts in PDR can translate to designing a more sustainable future

As the ecological problems that the world and its occupants face become increasingly evident, putting the planet’s needs at the heart of the design process has become a necessity for designers. We sit with our Senior Research Officer, Dr Katie Beverley (Katie B.) and our CMF Designer, Katie Forrest Smith, as they talk about how designers at PDR are using concept design to explore what this looks like in practice, the difference between concept and reality, and how we move from one to the other.

What capabilities are there for environmentally sustainable design at PDR?

Being a design and research centre, PDR combines commercial activity underpinned with rigorous academic research, allowing all kinds of capabilities for sustainable design spreading across many areas.

Katie B. explains, “Since we’re not limited to designing products at PDR, we’re not limited to designing more sustainable products. We’ve also designed services, policies and business models that contribute to a better future. For example, we worked with Zero Waste Scotland, the delivery body for resource management in Scotland, to conduct an audit on the design capacity for the circular economy in Scotland resulting in the creation of an action plan. We also worked with Riversimple, a manufacturer of hydrogen-powered fuel cell electric vehicles to help them explore business model alternatives that would make their whole operation more resource-efficient.

PDR has also incorporated sustainability into packaging design for clients. Katie Forrest Smith, our CMF Designer, continues, “A great example of how we integrate environmentally-sustainable design at PDR would be one of our first projects on packaging. A client came to us with their existing product which included packaging that was very bulky and was comprised of many materials that weren't easily recyclable. Our solution was to create something that was easily recycled, where materials could go somewhere at the end of life, as well as a hugely decrease the size. Reducing the size means a greater number of goods can fit in crates for shipment which in return can reduce fuel for transport. Not only did the end-product become all-round more sustainable, but it also massively reduced the production cost of the packaging for the client.”

What are the benefits of PDR’s research and commercial crossover?

One of the benefits of PDR’s crossover between research and commercial operation is our involvement in environmental sustainability-led design projects that can easily convert into concept designs.

“Usually, research is focused on things that are happening in the future, so often we’ll be trying to come up with very low TRL (Technology Readiness Level) solutions to future resource challenges,” Katie B. explains. “Researchers are often working right on the edge of what we currently know, but that gives great inspiration for new ideas and future-facing concepts. A good example of that was a project called Prestige, which was a European Horizon 2020-funded project, that explored sustainable futures driven by printed electronic materials.

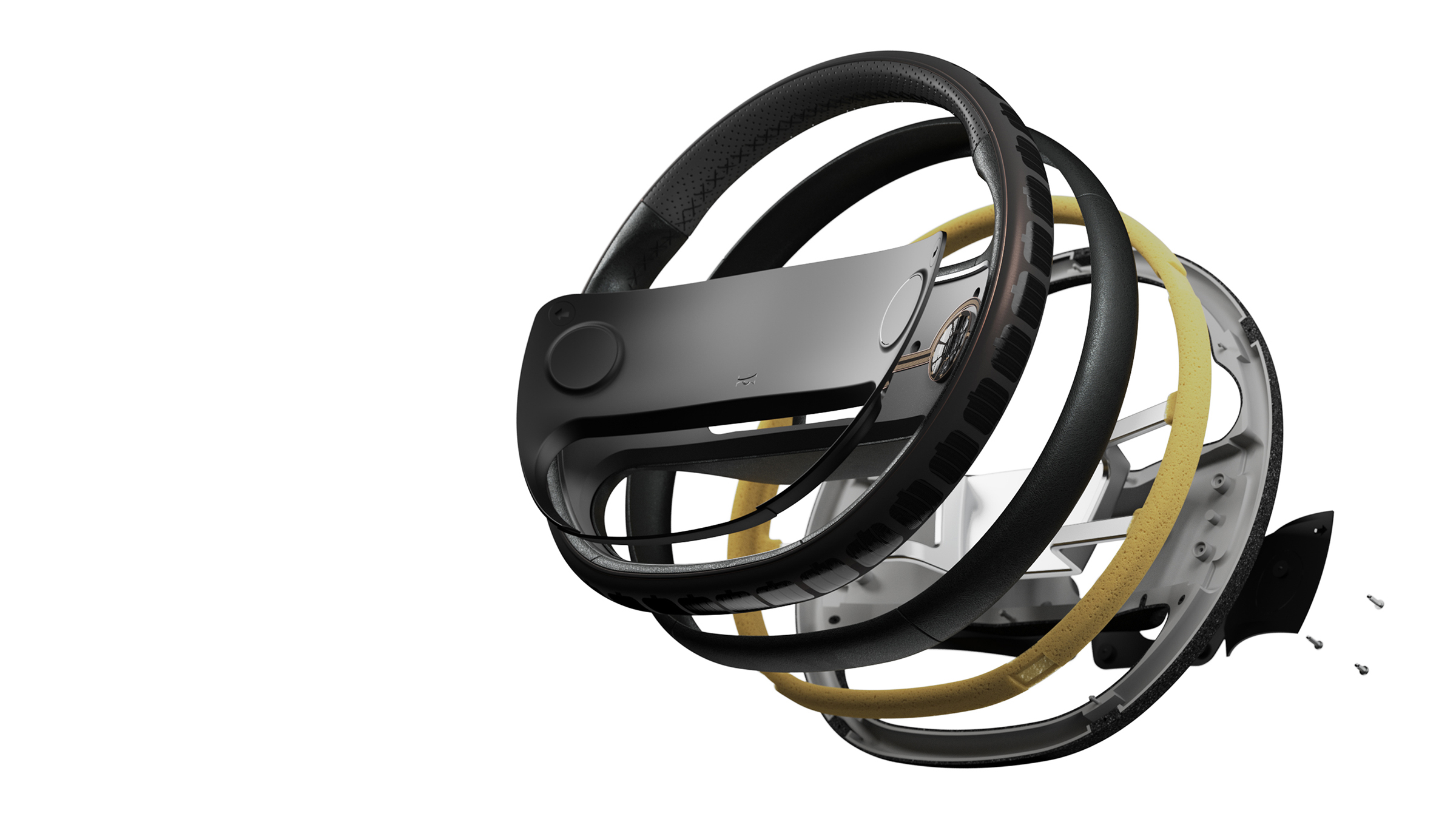

“One of the case studies was an automotive case study and the idea was that you would functionalize the steering wheels in the cars with printed electronics. But that led us to think about the challenges of what happens when things break. Do you just accept that the steering wheel is no longer intelligent because the structure is so complicated? Or do you think about how it might be taken apart and how you could potentially replace parts? This was the start of a concept that our designers worked on, which is called Cercle - a steering wheel that is designed for a more circular economy”.

Cercle is a perfect example of how research translates into concept design at PDR. Katie B. also mentions, “If we are presented with something we don't have much research on yet, we’ll take on the challenge and even do some in-house work!

“Recently we did a workshop with students from Cardiff Met. We set a 24-hour design challenge with them where we looked at PPE and the ideas that came out of that led to a concept called Umiko, a face mask designed to minimise waste and littering, an issue that was raised during the COVID-19 pandemic.”

What’s the difference between concept and reality?

In short, the concept is what the designers idealise as the solution; reality what is created when the constraints that inevitably emerge have been navigated. As Katie B. points out, “When we develop a concept, usually that’s right at the very beginning of something, you don’t have a lot of information.”

Katie Forrest Smith highlights that it is important not to be limited by what is currently possible, and to “create concepts that play with new materials that aren’t currently commercially viable.” By taking this approach with future materials that are more environmentally sustainable and embracing the freedom the concept design process allows, there is “room to be creative and think outside the box which in turn highlights which of those ideas can then be translated into real-world projects.”

Katie B. agrees. “Environmentally sustainable concepts are much more about pitching a direction than they are about creating something that will work out of the box – and not only for designers. Good concepts can inspire scientists and technologists to create the materials that will enable them to become reality – that’s a research field that we call design-driven materials innovation. So great concepts are almost a pathway to a better future.”

Good concepts can inspire scientists and technologists to create the materials that will enable them to become reality – that’s a research field that we call design-driven materials innovation. So great concepts are almost a pathway to a better future.

Dr Katie Beverley | Senior Research Officer | PDR

How do we move from concept to reality?

The move from concept to reality is really where the cogs start turning and most of the hard work is done. Ultimately, the aim is to turn a concept into something physical that can be realised with today’s materials, processes and technologies. Although a large proportion of concepts never see the light of day, Katie B. and Katie Forrest Smith don’t believe this should be seen as a problem. “The best concepts give a really inspiring start point, and although there will inevitably have to be compromises as it becomes apparent that some conceptual leaps can’t be realised, the really great designers in our commercial team have the skills to transform some of those conceptual ideas into brilliant real-world solutions.”

Next steps

Learn more about our work and get in touch if you’re interested in working with us.